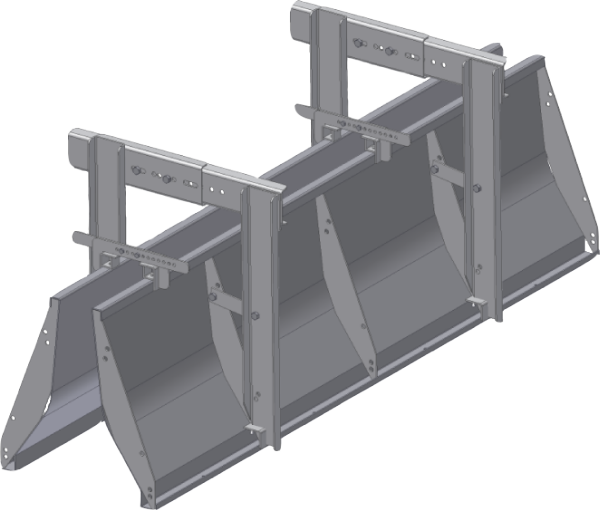

Parapet Forms

Top Spacers: (Adjustable from 6 - 12") assures uniform top thickness

Gussets are full height to maximize support and rigidity of each form

Form Aligner Assembly provides both vertical and horizontal form alignment

Top Spacers: (Adjustable from 6 - 12") assures uniform top thickness

Gussets are full height to maximize support and rigidity of each form

Form Aligner Assembly provides both vertical and horizontal form alignment

32" Barrier Forms with Moment Arms: (adjustable from 6" to 12") provides positive form alignment. These arms are designed for interchangeable use on either a double contour set-up or on a single contour set-up with a straight back.

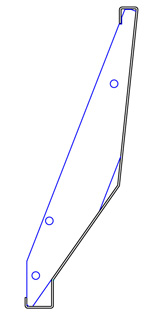

Contour Forms with V-bend

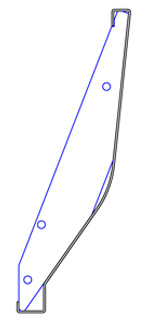

Contour Forms with Radius

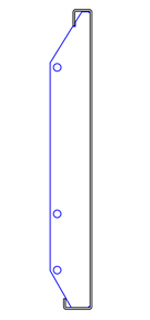

Straight Form Vertical

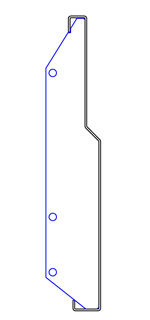

Straight Form with offset

SET-UP PROCEDURES

( using form aligners / turnbuckles )

- Anchor forms through base holes provided.

- Use wood or metal kicker outside of base (see drawing)

- Tie down through center of forms from top spacer to rebar (see drawing)

- Coil Taper Ties

- Coil rod with sleeve

- Snap ties